Our Value Proposition

| Goal | Services |

|---|---|

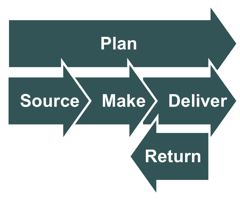

| Ensure seamless collaboration | Supply chain optimisation:

|

| Reduce spurious complexity | Transformation:

|

| Exploit information advantages | Business intelligence – aggregation of enterprise data and tacit domain expertise to uncover new insights |

| Improve business agility | Design of pricing engines:

|

| Improve internal and external communication | Enterprise content management:

|

Example Case Study

OrganisationClients in the Manufacturing and Logistics sectors |

StakeholdersChief Information Officers and Business Unit Managers |

GoalAdoption of lean manufacturing techniques and implementation of highly automated logistics systems. |

Context |

Client feedbackS23M Managing Partner Jorn Bettin introduced

|